Industrial Automation

With more than 17 years practise, Pooward automation solutions can fully meet customers’ needs to help them develop automatic production line & test Line, as well as specialized custom machines.

Automation Solution

Pooward automation solutions provide a more efficient, cost-effective and accurate way to monitor and control operations in production, assembly and testing. We help customers reduce costs associated with labor, energy, and materials, as well as improve safety, quality, and productivity. Our automation solutions can be tailored to specific needs and integrate with existing systems.

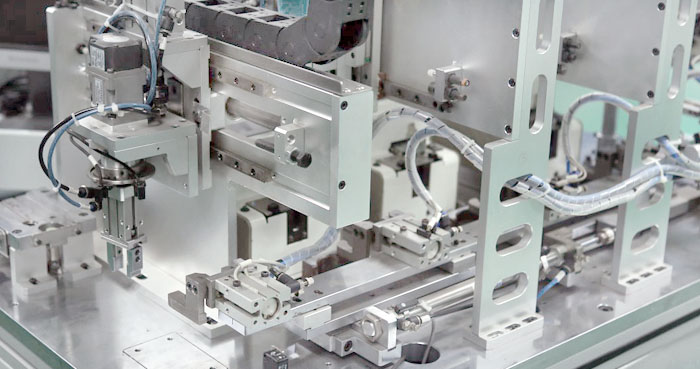

In-house Machining

Complete control over the machining process for cost savings, better quality control and greater flexibility.

Speedy Delivery

Deliver as fast as 2 weeks. 1 or 2 weeks for parts machining and another 1 or 2 weeks for assembly.

Cost-effective

Abundent resouces for materials and parts supply surounded enable us to cut down the overall cost

Engineering Suport

Suport from our experienced engineering team for designing, layout planing, assemblying and debbuging

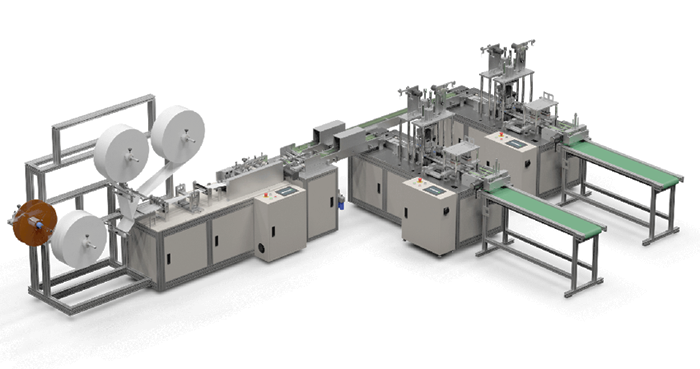

Automatic Production Line

Automatic production line comprised of a series of workstations linked by a transfer system, automated systems and an electrical control system to handle repetitive tasks in the production of a specific product. Each station performs a specific operation and the product is processed step by step as it moves along the line in a pre-defined production sequence. Automatic production lines can be used to produce a variety of products, from consumer goods to industrial components to increase efficiency and reduce the need for manual labor, resulting in cost savings and improved product quality.

benefits you can Get from

automatic Production Line

Successful Cases

Automatic Mask Production Line

Soft Pack Lithium Battery Sealing Line

Soft Pack Digtial Battery Sealing Line

Automatic Testing Line

Automated solutions for testing and quality control focuing on designing, installing, and maintaining test systems that are automated and integrated into the production line or manufacturing process. The test systems use data acquisition, analysis, and reporting software to analyze the performance of components and machines in order to determine product quality and identify issues that may lead to product failure. Automated test lines offer customers the ability to quickly and accurately test products before they are shipped to their destination.

Successful Cases

Capacities: 1200 pcs / hour

PCBA Multi-Station Test Lines

PCBA (Printed Circuit Board Assembly) Multi-Station Test Lines are automated production lines for testing and quality control of PCBAs. These lines are designed to test multiple aspects of PCBAs, such as electrical performance, signal integrity, compatibility with other components, robustness, etc. They can also be customized to meet customer specific requirements. The test lines typically incorporate a range of components including testing machines, conveyors, vision systems, and controllers, all of which are integrated into a single system. The lines are designed to provide accuracy, reliability, and efficiency with minimal manual intervention.

Features:

1. Modular design, compact structure, process and equipment can be increased or decreased according to actual needs;

2. It can automatically complete multiple processes such as PCBA feeding, code scanning, ICT inspection, and blanking etc.

Advantages:

PCBA high-speed code scanning

ICT detection and sorting

Application:

Consumer electronics & Semi-conduct

Power Battery OCV Testing & Sorting line

Soft Pack Battery OCV Testing & Sorting line

Custom Machinery

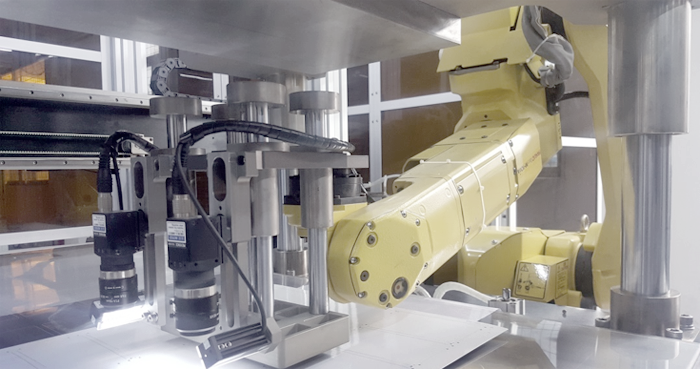

Custom machinery services specialize in the design, manufacture and installation of special purpose machinery for use in the manufacturing process. We provide complete solutions, from initial concept to installation, to ensure that the machinery is tailored to meet the specific needs of the client. The services can include the design and manufacture of machines, the installation and programming of robotic systems, and the integration of sensors and controllers.

Successful Cases

CNC Machining Center

Automatic Laminator for Auto Battery